Powering Real-Time Motion Control in Digital Twin Gantry Welding Robots with Industrial Ethernet Switch

|

||

|

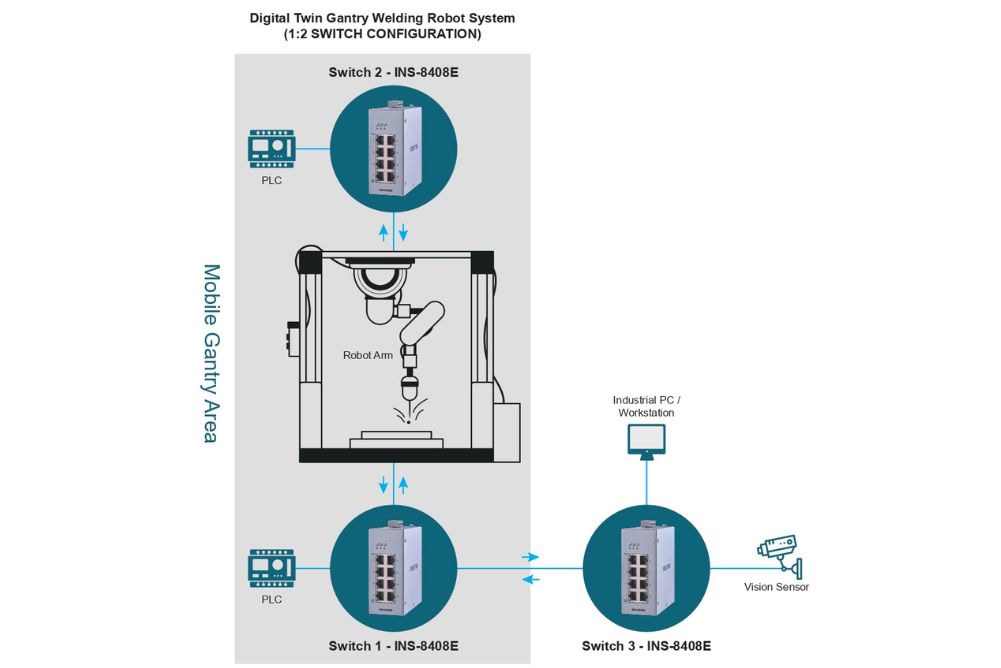

Developing a Digital Twin Gantry Welding Robot system requires more than advanced robotics—it needs a resilient network foundation that can keep high-speed vision, multi-axis motion, and AI-driven control working flawlessly together, even in harsh steel manufacturing environments. Recognizing these demands, Volktek was selected to provide the critical foundation that enables the system's success.

To meet this highly synchronized and data-intensive application, the INS-8408E industrial Ethernet switch was chosen to address the key networking challenges that arise when such technologies converge, including:

To maintain weld accuracy and prevent costly downtime, the customer needed a reliable industrial Ethernet solution engineered to operate where ordinary switches cannot. |

Volktek's Solution |

||

| The customer required a network device purpose-built for automation—something commercial switches could not provide. | ||

|

Volktek's INS-8408E industrial Ethernet switch was selected because it directly addresses the challenges of precision welding environments.

|

||

| Together, these capabilities allow the INS-8408E to deliver the reliability and timing precision required for safe, consistent welding automation—even under harsh industrial conditions. | ||

|

||

Deterministic low-latency communication keeps robotic arms and gantry movement perfectly aligned.

Gigabit throughput ensures uninterrupted video streaming for real-time inspection and AI decision-making.

Designed for extreme temperatures, vibration, and EMI—conditions where commercial switches often fail.

Zero-configuration operation shortens installation time and simplifies integration into manufacturing cells.

Redundant power inputs ensure continuous operation during power instability.

|

Facing similar demands in your automation or digital twin systems? Volktek's industrial networking experts can help you design a stable, reliable foundation that keeps your operations running flawlessly. |

||

|

Contact Our Experts |