Application Overview

To increase productivity, efficiency and accuracy, industries commonly use programmable robots for repeatable operations such as welding, gripping, spinning, and fitting. The data is sent through a PLC (Programmable Logic Controller) to a SCADA system to be analyzed so that robots can be remotely controlled. The Ethernet devices connected to the PLC need to be robust and reliable and able to withstand harsh factory environments.

Key Considerations

Key Volktek Benefits

| Feature | Benefit | ||

| Reliability | Redundant Power and Alarm Relay | Remains On During Power Failure and Notifies Users | Built-in surge protection, dual power sources, and battery backup ensure stable device operations for 24/7 network reliability. |

| Availability | Plug and Play Feature, Auto-recognition | Recognizes devices once plugged. | Built-in The Plug and Play feature allows devices to communicate once plugged without extra device installation needed to speed up the process of installation and avoid any conflicting device communication. |

| Performance |

LLDP Filter | Blocks the LLDP packets exchange at unmanaged devices without disturbing managed ones. | During the network discovery process device flapping issue can be occurred when the peripheral devices are connected to an unmanaged switch in the network. The Link Layer Discovery Protocol (LLDP) Filter blocks the LLDP packets exchange at unmanaged devices without disturbing managed groups to avoid the device flapping issue. |

| VLAN Passthru | Connect Remote Devices | Helps to communicate with different devices by receiving and transmitting VLAN packets without losing or configuring them. | |

| Modbus and PROFINET | Support Industrial Protocols | PROFINET is an industrial standard for data communication over industrial ethernet, designed for low-latency data collection and controlling equipment. Modbus is a serial communication protocol typically used to transmit signals from instrumentation and control devices back to a main controller or data management system. |

|

| Quality of Service (QoS) | Define the Critical Networks | Networks typically operate on a best-effort delivery basis, which means that all traffic transmitting from ports has equal priority and chance of being delivered in a timely manner. When congestion occurs, the same traffic has an equal chance of being dropped. When configuring the QoS feature, specific networks can be prioritized, optimizing the network performance and bandwidth utilization. | |

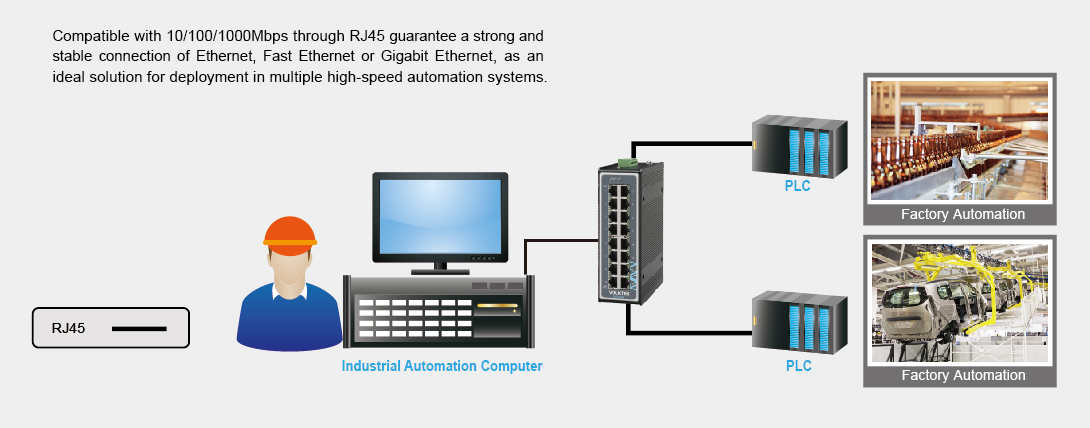

Application Diagram